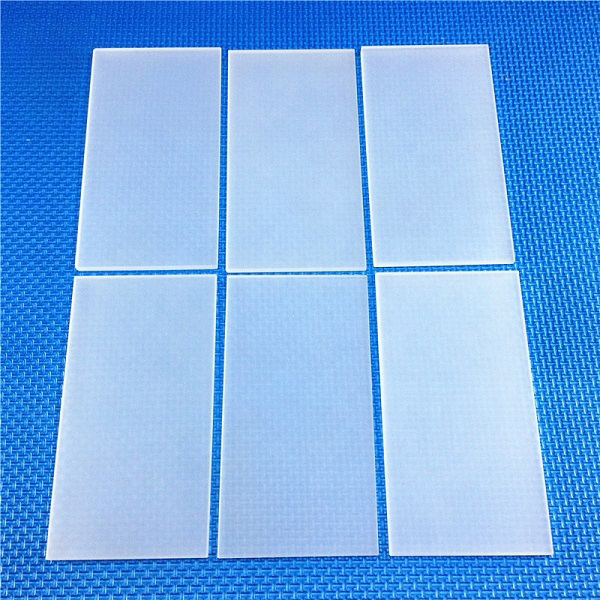

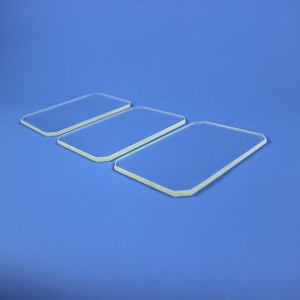

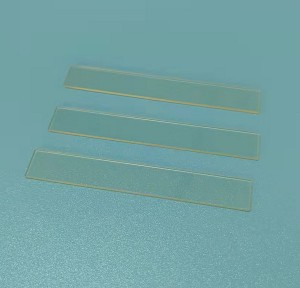

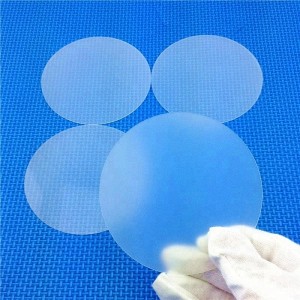

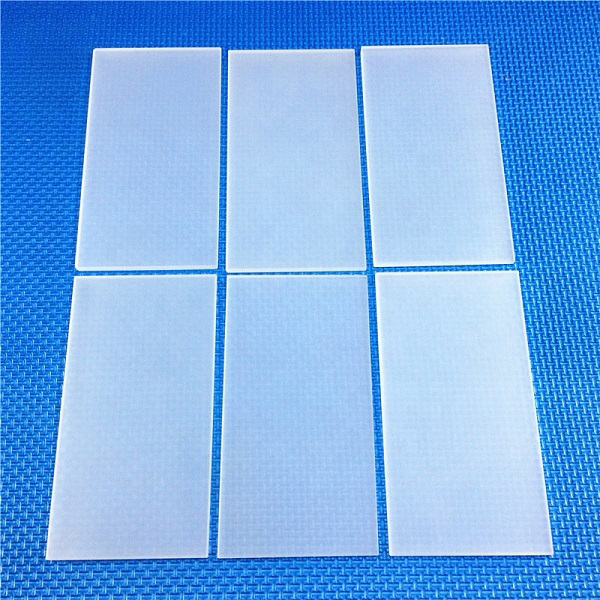

Ipleyiti yeQuartz eFrosted kwiFactory

Siyakwazi ukwenza iJGS1/JGS2/JGS3 izilayidi zeglasi yequartz ekhenkcezayo, isetyenziswa kakhulu kumatshini oxhathisa ubushushu obuphezulu okanye enye indawo.Umphezulu unokugudiswa okanye ube neqabaka njengemfuneko, kunye nelogo elungiselelweyo.Ndixelele ubude,ububanzi,ukutyeba, macala omabini ipolishiwe okanye hayi.siya kukuthumelela elona xabiso lilungileyo kungekudala.

Inkcazo

| Ubume | Ubude/OD | ububanzi | ubukhulu | Umgangatho womphezulu |

| Umjikelo | 0.5mm ukuya 1200mm | 0.05mm ukuya 500mm | 80/50,60/40,40/20,40/20,20/10 | |

| isikwere | 0.5mm ukuya 1200mm | 0.5mm ukuya 1200mm | 0.05mm ukuya 500mm | 80/50,60/40,40/20,40/20,20/10 |

| Ukunyamezela: ± 0.02mm ukuya kwi-2mm | umthengi | |||

| Obunye ubungakanani bunokwenziwa ngokweemfuno zabathengi | ||||

Izinto eziphathekayo

I-Quartz edibeneyo

I-Silica edibeneyo

Iglasi yequartz ye-infrared

Corning® 7980

Corning® 7979

Izinto eziluncedo kwimveliso

1. Ukumelana nobushushu obuphezulu.

Indawo yokuthambisa yeFused silica glass sheets imalunga ne 1630 ℃. Ingasetyenziswa kwi-1100 ℃ ixesha elide, kwaye ubushushu obukhulu bunokufikelela kwi-1450 ℃ ngexesha elifutshane.

2. Ukuzinza kakuhle kwe-thermal

I-coefficient yokwandiswa kwe-thermal yamaphepha e-quartz edibeneyo incinci kakhulu, kwaye inokumelana nokutshintsha okukhulu kweqondo lokushisa. Xa iidiski zequartz ezidityanisiweyo zifudunyezwa malunga ne-1100 ℃, aziyi kugqabhuka kumanzi obushushu obuqhelekileyo.

3. Ukuhanjiswa kokukhanya okulungileyo

I-quartz substrates edibeneyo inokuhanjiswa okulungileyo kuyo yonke ibhendi ye-spectral ukusuka kwi-ultraviolet ukuya kwi-infrared. Ukuhanjiswa kokukhanya okubonakalayo kungaphezulu kwe-93%, ngakumbi kwingingqi ye-ultraviolet spectral.

Iimveliso ezibonisiweyo

Iimbonakalo

| SIO2 | 99.99% |

| I-Coefficient yoKwandiswa | 5.54 x 10-7 (K-1) |

| Iqondo lobushushu leNgxaki | 1343 isidanga K |

| Inqaku lokuthambisa | Ngowe-1933 isidanga K |

| I-Thermal Conductivity | 1.37 W/m 0K |

| Iqondo lobushushu leNdawo eAnealing | 1433 0K |

| Ubushushu obuthile obuqhelekileyo - | 771 J/kg.K |

| Ubushushu bokusebenza obuLungileyo | 1423 - 1473 0K |

| I-Specific Heat Conductivity | 1.48 W/mK |

| Ukunyamezela i-Acid | Amaxesha angama-30 kune-ceramic, amaxesha angama-150 kune-stainless |

| Ukuxinana | 2.204 g/cm3 |

| Tensile strength | 49 N/mm2 |

| Umlinganiselo wePoisson (Akukho yunithi) | 0.17 |

Usetyenziso

Ipleyiti yequartz / idiski yequartz engqukuva / iglasi yokubona yequartz yayisetyenziswa ngokubanzi kumhlaba olandelayo:

1) Izixhobo zoomatshini, iShishini lokuKhuselwa kokusiNgqongileyo,

(2) Izixhobo zePlasma Processing

(3) I-Aerospace, i-Commerce Industrial

(4) Umkhosi, uKhuselo, i-Electronics

Ixesha lokukhokhela

Ngamalungu esitokhwe, siya kuthumela ngaphandle kwiveki enye. Ukuze ufumane iinkcukacha ezithe vetshe, nceda uqhagamshelane nathi. Ukuba unesidingo esingxamisekileyo, siya kulungiselela kuqala.

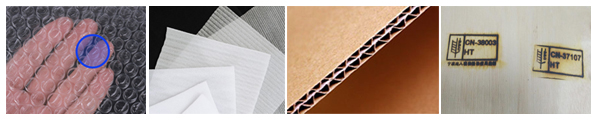

Ukupakisha okuKhuselekileyo

1. Ukusonga iqamza

2. Izinto zogwebu

3. Ibhokisi

4. Ityala lomthi

Wamkelekile ukuba uqhagamshelane nathi ngezantsi ukuze ufumane inkcazelo engakumbi!